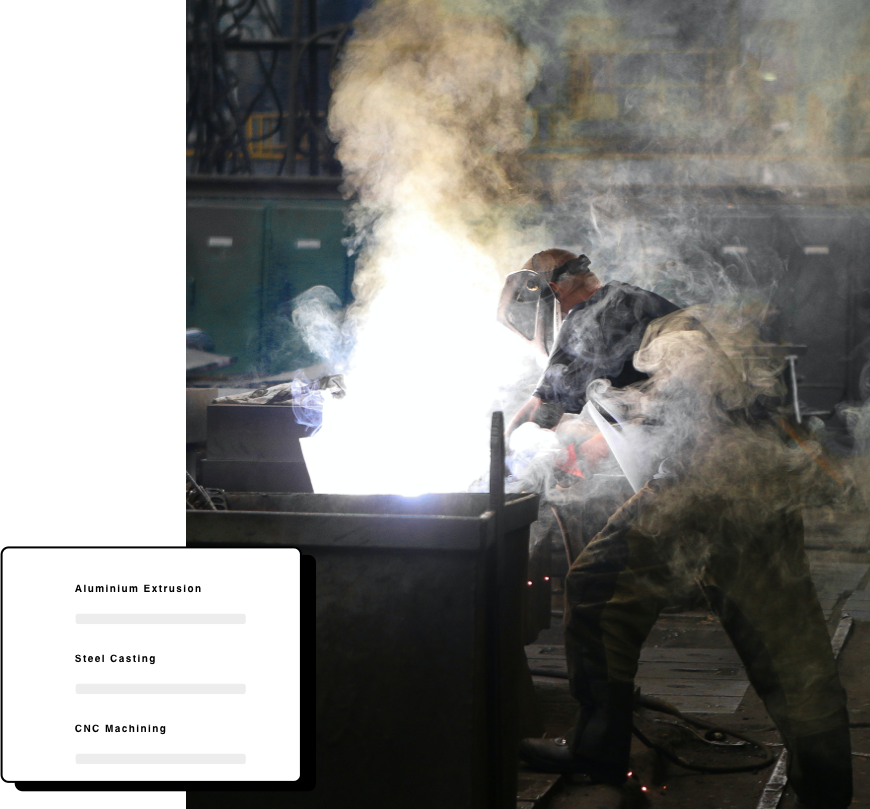

All casting and metalworking techniques

We use several different casting techniques, including sand casting, die casting, and investment casting, each with its own unique advantages and applications.

We offer the best cost-benefit solution in Canada

The benefits of Aluminium Casting

One of the biggest advantages is the ability to create complex shapes and intricate designs, which would be difficult or impossible to achieve with other manufacturing processes. Aluminium casting is also highly efficient, allowing for the production of high volumes of parts in a short amount of time. Additionally, aluminium casting can be cost-effective for producing large quantities of parts, as the per-unit cost decreases as the quantity increases.

Who is Aluminium Casting for?

Aluminium casting is used by a variety of industries, including automotive, aerospace, construction, and consumer goods. It’s ideal for creating high-strength, lightweight parts with good corrosion resistance. Aluminium casting is also a popular choice for companies looking to manufacture products at a lower cost, as the process can be highly automated and the molds can be reused.

How can alumiunium casting help you save costs

Aluminium casting can help your company save costs in several ways.

- The process is highly automated, which reduces labor costs and increases production efficiency.

- The molds used in aluminium casting can be reused, which lowers the cost of tooling.

- Aluminium casting can help reduce material waste, as the process can be finely tuned to minimize excess material usage.

- Casting can help reduce the need for secondary operations, such as machining or assembly, which can further lower costs.

A turnkey procurement management solution.

Running a business today is complicated enough. Your procurement solution should be simple. Spend less time managing your procurement and more time running your business.

Ready to take action ?

Find out how Moldeck can help you manufacture high quality products at a fraction of the price