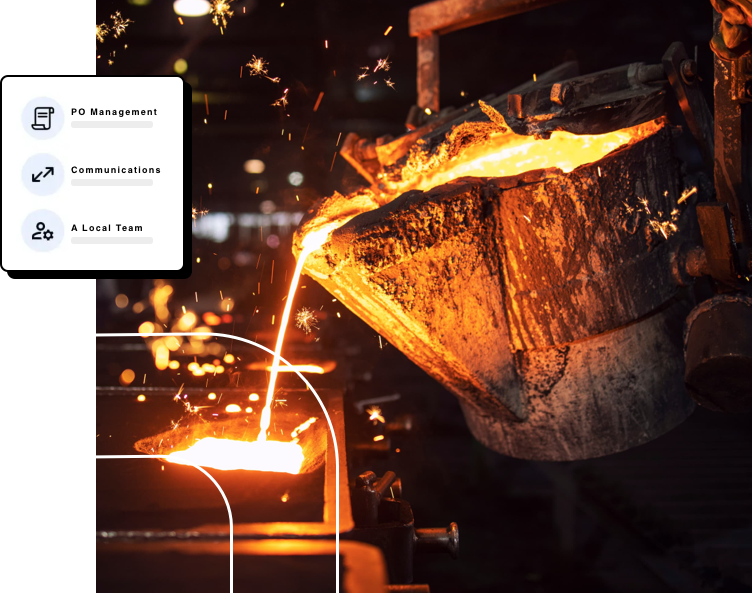

We use three main types of casting

Precision lost wax casting

By means of the silica sol process , which is especially suitable for precision products in stainless steel

Waterglass casting

The waterglass technique is comparable in surface area to sand casting and is used for casting steel

Iron casting

Through sand casting we produce cast iron products for various applications

The benefits of precision casting

- Design flexibility – Produces complex parts with intricate geometries.

- High accuracy – Maintains consistent dimensions and tolerances for precision parts.

- Material options – Can cast a wide range of metals and alloys.

- Cost-effective – Ideal for small to medium production runs.

Why use casting?

Precision casting is an excellent choice for anyone looking to produce complex metal components with high accuracy and consistency.

It is especially well-suited for industries such as aerospace, automotive, medical, and defense, where the production of small, intricate components is essentia

We also specialize in casting high-quality products made of aluminium

Our injection molding machines are fully automated and advanced robots ensure a more efficient casting process

Read our story

A turnkey solution to streamline your operations

Running a business today is complicated enough. Your procurement solution should be simple. Spend less time managing your procurement and more time running your business.

Ready to take action ?

Find out how Moldeck can help you manufacture high quality products at a fraction of the price